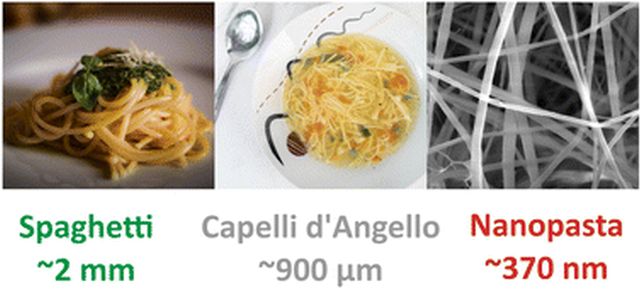

What you are looking at in the image above bears a strong resemblance to spaghetti. That’s because it is spaghetti – but unlike any spaghetti ever made before.

At just 372 nanometers across – around 200 times thinner than a human hair – these are the thinnest spaghetti strands the world has seen, some 1,000 times thinner than the famous, 440,000 nanometer-wide su filindeu of Sardinia.

But the new nanosketti is not for eating. It’s for science. Specifically, it’s for medicine, with potential applications for the healing of wounds, among other possibilities.

The extrusion of teeny-tiny nanofibers derived from flour means we could rely less on directly-sourced plant nanofibers that are more expensive and difficult to create.

“To make spaghetti, you push a mixture of water and flour through metal holes. In our study, we did the same except we pulled our flour mixture through with an electrical charge,” explains chemist Adam Clancy of University College London. “It’s literally spaghetti but much smaller.”

Starch nanofibers show excellent promise for several medical applications. They are flexible and have a high surface area, but are also biodegradable, biocompatible, porous, and easy to modify chemically. This means that they could be used for a bunch of things, including drug delivery, wound healing, and even bone regeneration.

“Nanofibers, such as those made of starch, show potential for use in wound dressings as they are very porous,” says pharmaceuticals materials scientist Gareth Williams of University College London.

“In addition, nanofibers are being explored for use as a scaffold to regrow tissue, as they mimic the extra-cellular matrix – a network of proteins and other molecules that cells build to support themselves.”

Deriving starch nanofibers directly from plants is a process that is both energy and water intensive. A team led by chemist Beatrice Britton of University College London thought that there might be another way – creating the fibers from a starchy plant-based material that is already produced cheaply around the world. That’s flour.

But flour isn’t only starch. It also contains materials like protein and cellulose, which complicate the electrospinning process. As anyone who has cooked with flour knows, combining it with water can make for a gluggy and viscous gloop – great for roux or pasta or bread, but somewhat less helpful for nanofiber spinning.

Electrospinning is a process that uses an electrical charge to attract and guide material through a tiny hole. Getting this to work on flour required a substitution: rather than using water, the team moistened the flour with formic acid (what is this? Spaghetti for ants?) to break apart the tiny helical structures that make starch. Then, as the material exits the tiny hole, the acid evaporates, leaving just the nanospaghetti behind.

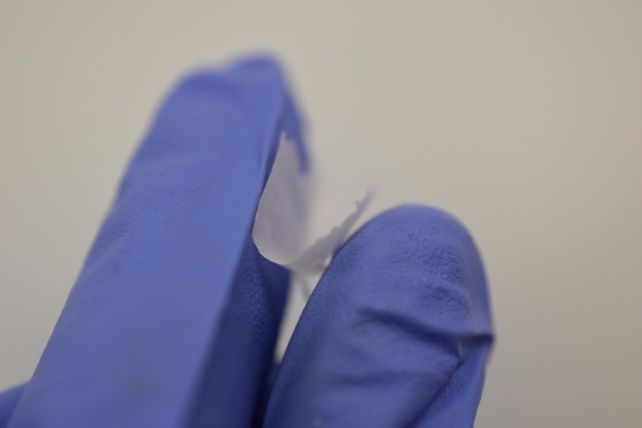

The resulting strands quickly tangle into a flexible, hydrophilic mat of nanofibers. At about 2 centimeters (0.8 inches) across, each strand is too small to see individually, so the researchers probed the mat with a scanning electron microscope to measure what they had spun.

Materials made this way could be a cheaper, greener alternative to those made with other plant starch nanofibers. But first, the scientists have to investigate their properties to see how quickly they break down, how they interact with various chemicals, and whether their manufacture could be scaled up.

Unfortunately, as is often the case when scientists get their hands on pasta, we don’t get to eat it.

“I don’t think it’s useful as pasta, sadly, as it would overcook in less than a second, before you could take it out of the pan,” Williams says.

Sad trombone.

The research has been published in Nanoscale Advances.