by Annette Siller, Technologie Lizenz-Büro (TLB) der Baden-Württembergischen Hochschulen GmbH

Wound dressings should provide sterile coverage, protect the wound, and adhere reliably, while still allowing for painless removal. It is essential that the process of skin renewal remains undisturbed.

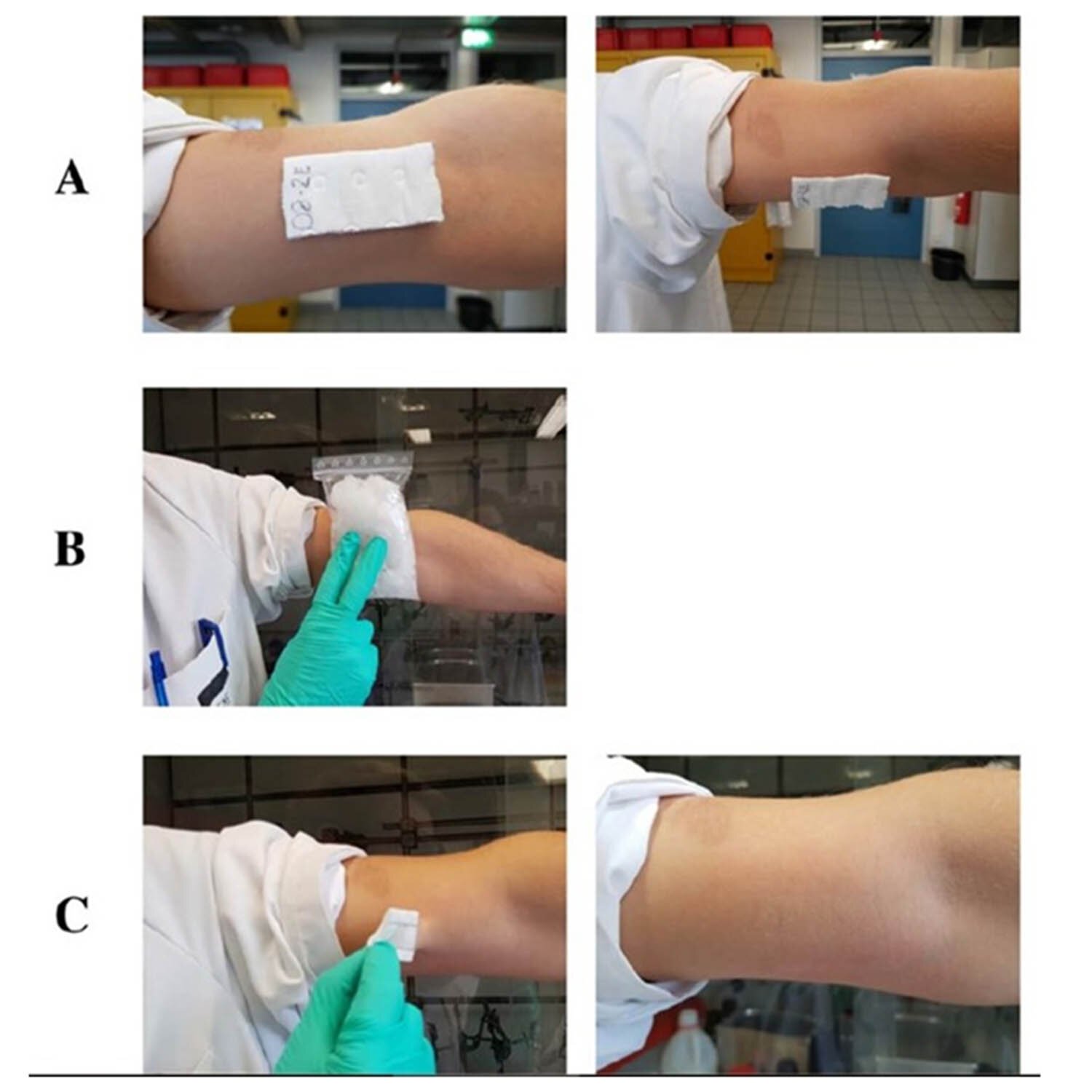

A newly developed approach in wound care involves dressings that adhere firmly to the skin at body temperature but can be removed easily and painlessly with the application of a cold pack.

Currently, the majority of self-adhesive wound dressings rely on a zinc oxide rubber adhesive system developed more than 100 years ago. The removal of these dressings can be very painful and may damage regenerated tissue.

Consequently, for more than 30 years, research has focused on alternative adhesive materials based on the “bond/debond-on-demand” principle. This is because no suitable solutions currently exist for individuals with allergies, burn wounds, or chronic wounds, such as those in diabetic patients.

Researchers at the University of Freiburg have developed an innovative polymer for wound dressings that adheres securely under temperature control but is easy to remove. This approach enables dressings to adhere firmly to the skin or wound site at body temperature without restricting the patient’s freedom of movement.

When the dressing is cooled, however, such as with a cold pack, it can be removed very easily and without pain. Additionally, no adhesive residue remains on the healing tissue. The adhesive material’s property of “switchable stickiness” is achieved through a crystallization process.

The research team at the Institute of Macromolecular Chemistry at the University of Freiburg, led by Prof. Dr. Rolf Mülhaupt and Prof. Dr. Thorsten Steinberg, who supervised the project from a medical perspective at the Freiburg University Medical Center, developed an adhesive consisting of copolymers and polyvinyl alcohol (PVA) fatty acid esters with crystallizable side chains and varying compositions.

The strategy is based on thermoresponsive polymers, which are solid at room temperature and molten at body temperature, exhibiting adhesion only in the molten state. Cooling induces crystallization of these side chains, resulting in a loss of adhesion to the skin.

Crystallization causes physical cross-linking of the material, significantly inhibiting adhesion to the skin while increasing the material’s cohesion. This allows the dressing to be removed in one piece without leaving any adhesive residue and without causing pain.

Simultaneously, the volume is reduced, decreasing the contact surface between the wound dressing and the skin, facilitating detachment.

In application, the material changes due to body heat and adheres accordingly. By applying a cold pack, the material crystallizes and no longer adheres to the skin. The material does not enter the wound.

This wound dressing is particularly suitable for burns, allergic or sensitive skin, or infected wounds, as it prevents skin injuries or detachment. This type of wound dressing is also ideal for inpatient wound treatment or for large wounds, as it leaves no adhesive residue and exhibits excellent biocompatibility. A patent application has been submitted for this invention.

Provided by

Technologie Lizenz-Büro (TLB) der Baden-Württembergischen Hochschulen GmbH

Citation:

Researchers create innovative polymer wound dressings for painless and residue-free removal (2024, June 17)

retrieved 17 June 2024

from https://phys.org/news/2024-06-polymer-wound-painless-residue-free.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.