The surge in the adoption of renewable energy, coupled with the rapid growth of the electric vehicle market in recent years has significantly increased the demand for high-performance, all-solid-state batteries.

Compared to conventional liquid electrolyte-based batteries, solid-state batteries offer higher energy density, improved safety, longer lifespan, and reliable operation over a wide temperature range.

However, there are still challenges to their widespread applications, including low ionic conductivity, high interfacial resistance, and the presence of particle-particle interfaces in the electrolyte, which leads to increased resistance and lower energy density.

Notably, research on high-performance solid electrolytes has primarily focused on inorganic and organic solid electrolytes. While inorganic solid electrolytes transport only lithium ions, organic solid electrolytes allow the migration of anions and other species. However, this leads to side reactions at the electrodes, resulting in reduced capacity and adverse effects, such as decreased battery performance and lifespan.

In contrast, inorganic electrolytes are less prone to side reactions, offering longer battery life and higher performance. Nevertheless, they have their own challenges. For instance, oxide-type inorganic solid electrolytes suffer from reduced stability and require high-temperature sintering, whereas sulfide-type electrolytes react with atmospheric moisture, generating toxic hydrogen sulfide gas.

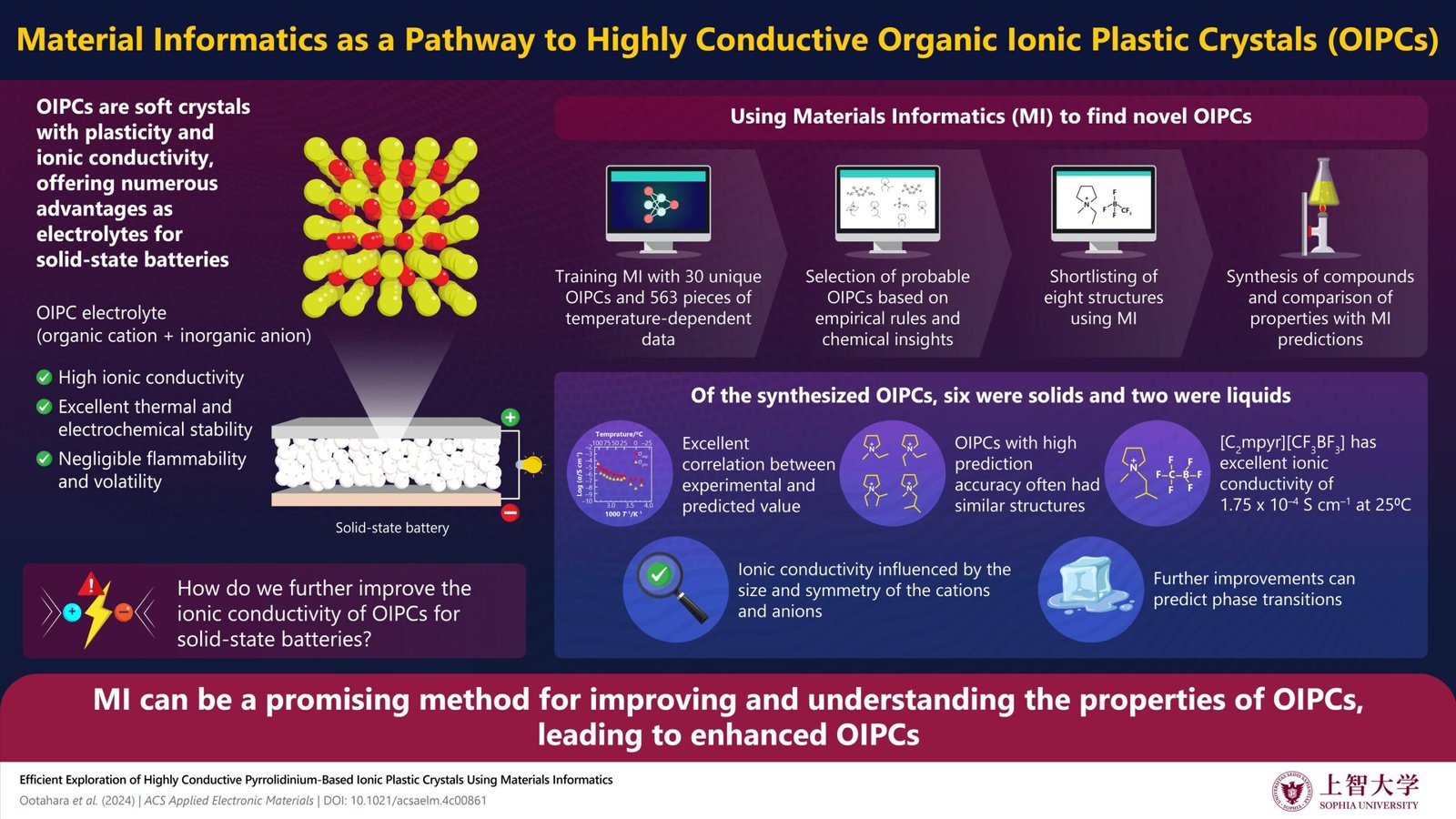

To address these issues, researchers from Japan undertook a new study by turning their focus toward organic ionic plastic crystals (OIPCs). The research is published in the journal ACS Applied Electronic Materials.

OIPCs consist of an organic cation and a suitable inorganic anion together with the lithium salt of the same anion. Being entirely composed of ions, these materials offer high ionic conductivity, high stability, and negligible flammability, making them highly suitable as solid electrolytes for batteries.

A notable feature of OIPCs is their phase transition between the solid crystalline phase and the liquid phase, called the plastic crystal phase. Despite these advantages, for practical applications, OIPCs still need higher ionic conductivity.

In the study, the research team, led by Professor Masahiro Yoshizawa-Fujita from the Department of Materials and Life Sciences at Sophia University, along with Takuto Ootahara and Morgan L. Thomas, also from Sophia University, and Kan Hatakeyama-Sato from Tokyo Institute of Technology, utilized material informatics (MI) to explore highly conductive OIPCs.

“MI leverages informational science, such as statistical science and machine learning, for efficient material development. In this study, we explored OIPCs by combining empirical rules and a machine learning-based MI model,” explains Prof. Yoshizawa-Fujita.

First, the researchers created a training dataset using chemical structures and conductivity data from OIPC-related literature and verified the prediction accuracy of the MI model on two test compounds. The validation results showed that the prediction accuracy improves when the training data includes similar chemical structures.

Therefore, the researchers selected pyrrolidinium cations, which were well-represented in the training data, as candidate substances. Furthermore, based on empirical rules from previous studies on enhancing ionic conductivity in pyrrolidinium cation-based OIPCs, they used MI to further narrow down the candidate substances.

As a result, the team successfully synthesized eight new compounds, including six OIPCs and two ionic liquids. Among these, one compound exhibited excellent ionic conductivity of 1.75 × 10-4 S cm-1 at 25°C, which is among the highest reported value to date.

Notably, the MI results also revealed new insights into the relationship between ionic radius and ionic conductivity of OIPCs. Conventional empirical rules suggest a lower ionic radius to ionic conductivity ratio is desirable.

However, the newly synthesized compounds indicate that an optimal value exists. Additionally, the MI model predicted discontinuous changes in the OIPC structure, suggesting that further improvements in prediction accuracy can also enable the prediction of phase transitions.

Explaining the potential benefits of the new OIPCs, Prof. Yoshizawa-Fujita says, “The development of high-performance solid electrolytes will increase the safety of rechargeable batteries, as there will no longer be a concern about liquid leakage.

“Also, it will increase the energy density of these batteries, making devices equipped with batteries lighter and more compact. For example, OIPC-based rechargeable batteries can increase the range of electric vehicles and promote their widespread adoption.”

Overall, these findings demonstrate the potential of MI to advance our understanding of OIPCs, paving the way for the development of safer, high-performance, and next-generation rechargeable batteries.

More information:

Takuto Ootahara et al, Efficient Exploration of Highly Conductive Pyrrolidinium-Based Ionic Plastic Crystals Using Materials Informatics, ACS Applied Electronic Materials (2024). DOI: 10.1021/acsaelm.4c00861

Citation:

Material informatics aids in developing high-performance solid electrolytes for rechargeable batteries (2024, October 7)

retrieved 7 October 2024

from https://phys.org/news/2024-10-material-informatics-aids-high-solid.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.