Fresh hope is on the horizon for ecologically safer pesticide ingredients, thanks to the ingenuity of a research team at the University of Delaware.

Insecticides are often considered a foundational part of agricultural production, designed to protect crops used to feed the world’s growing population—8.2 billion people and counting as of 2024.

But pesticides often present a conundrum. You want the ingredients to work for a given problem, but you don’t want them to be so broad that they unintentionally harm non-targeted species or the environment.

Now, a research team led by UD Professors Dion Vlachos, a chemical and biomolecular engineer, and Michael Crossley, an entomologist and wildlife ecologist, have synthesized new active insecticidal ingredients that are target-specific and ecologically safer than conventional pesticides.

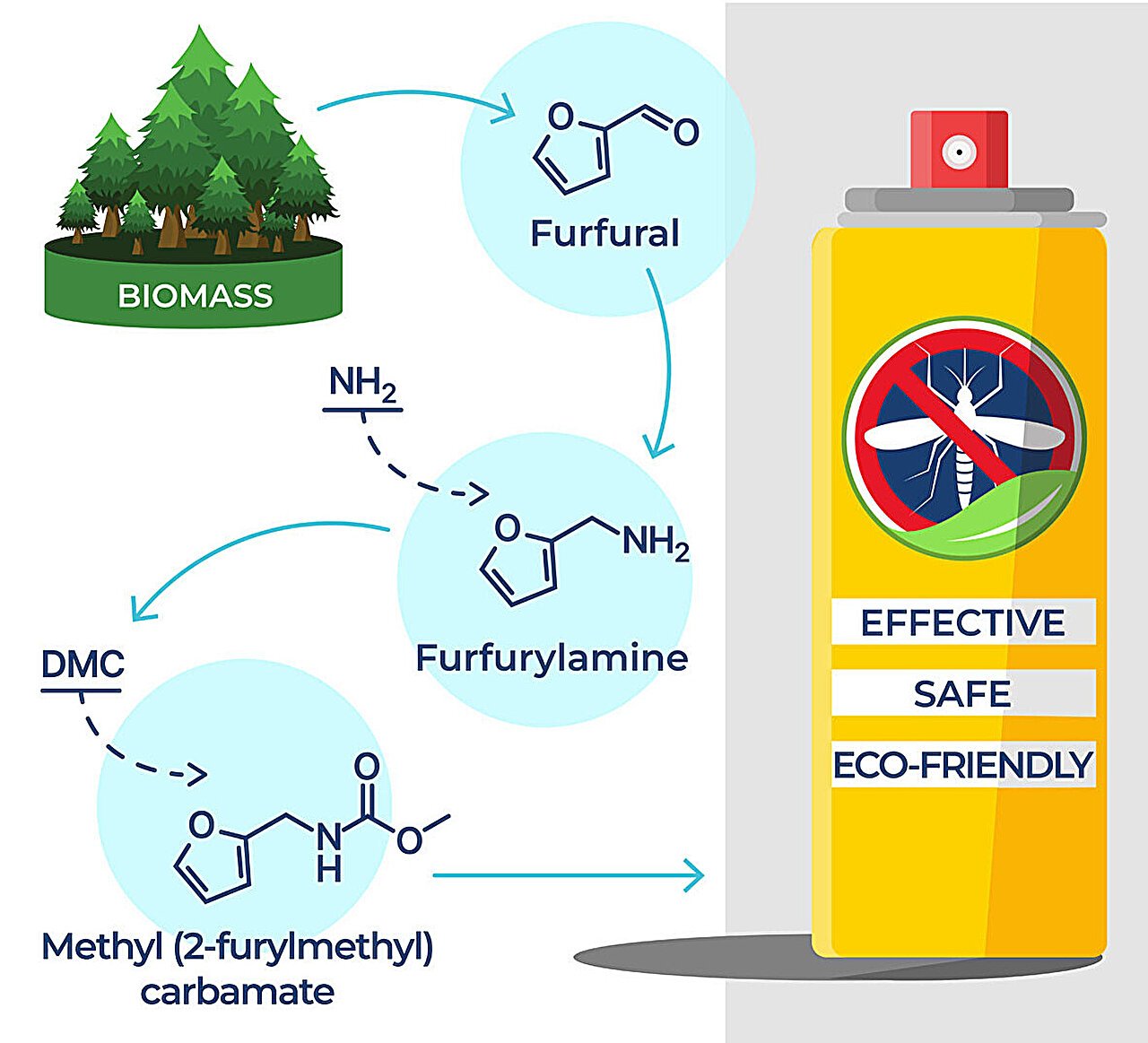

The chemistry and molecules are derived from biomass materials such as wood pulp, straw and corncobs —resources otherwise considered waste, bringing sustainability and circularity to the work. The researchers published their findings in ChemSusChem.

Synthesizing new molecules

Simply put, the research team figured out a way to take commercially available plant-based atoms from biomass and precisely graft specific functional molecules onto them to create a new type of chemical with the potential to impart the desired insect-killing activity.

Sunitha Sadula, lab manager and senior scientist at the Delaware Energy Institute, described the bio-based molecules as “bridging molecules” between caustic solutions currently in use and more sustainable, ecologically friendly methods.

“The big-picture motivation was to address the need for minimizing or ideally eliminating toxic chemicals on our food, in our water resources and in our environment,” said Sadula.

The research team tested their formulation on a synthetic molecule known as vanillin, which is commonly produced from lignin, a component of plants and trees that provides structure and stability. They also tested a molecule known as furfural, which is derived from sugar molecules present in lignocellulosic biomass, the most abundant waste material left over from the pulp and paper industry.

Once they had a material that looked promising, the researchers enlisted the help of Michael Crossley, assistant professor of entomology and wildlife ecology in UD’s College of Agriculture and Natural Resources, to determine if the molecule the team had created was a pesticide.

In his tests, Crossley found that the UD-developed molecules and process did work as an effective insecticide on a pest known as the lesser mealworm beetle, causing levels of mortality similar to conventional insecticides.

“What’s amazing about the process that the Vlachos lab worked out is that you can remove a group and add a group. And suddenly, it’s a different type of chemical with totally different properties,” said Crossley. “Right now, they’re making some chemicals that have structural similarities to much safer insecticides with more targeted effects.”

More testing is needed to ensure that the UD-developed pesticide molecule does not harm ecologically beneficial insects, such as honeybees, Crossley said.

Tuning and recreating chemistry with a sustainability mindset

Tejas Goculdas, a fifth-year doctoral student in the Vlachos lab, said others have tried different strategies to make these types of bio-based pesticides, even from lignocellulosic biomass, but were not able to make active ingredients specifically achieving the same toxicity activity as commercial pesticides. The UD-developed method, however, achieved a bio-based pesticide with nearly equal effectiveness (nearly 1:1) to traditional carbamate-based pesticide ingredients available on the market.

And while current commercial pesticides are typically derived from fossil fuels and other toxic reagents and chemicals with known harmful effects, the UD-developed method uses completely renewable chemicals to make these active ingredients from biomass. With at least 991 million tons of available dry lignocellulosic biomass in the United States each year, it’s a sustainable option, too.

Crossley pointed to the team’s ability to create useful chemicals from waste as a major advantage in addressing the need for circularity when devising solutions to problems.

“I just love the idea of this recycling,” Crossley said.

Additionally, the ingredients are less toxic to the environment and more affordable in price than other commercially available options. The team used minimal steps to produce the products and eliminated highly toxic reagents typically used during commercial synthesis, bringing sustainability to that part of the product development process, too.

Based on the active ingredients, a technoeconomic analysis found the team’s furfural-based molecular compounds are two to four times cheaper than other commercially available compounds widely used to make pesticide products.

Importantly, it’s scalable.

“In designing the chemistry, we focused on starting with molecules that are commercially available, so that we wouldn’t face supply chain challenges when we wanted to scale up,” Sadula continued.

The UD research team has filed an international patent application on their method and process through UD’s Office of Economic Innovation and Partnerships (OEIP).

One surprising finding from the research was how safe the furfural-based compound would be for aquatic organisms. This is because the chemistry of the UD-developed molecules prefers an aquatic environment, so the molecules would prefer to remain in the water, not in an organic organism, like plants, soils or fish.

“This means that it’s easier to get these chemicals off various fruits or vegetables because you can just wash them off,” said Goculdas.

An interesting element of the UD-developed method and process is that it allows for taking out one molecule and inserting another, opening the door—or mind—to consider other ecologically or environmentally caustic materials currently used to grow food and whether there are ways to make those solutions greener or more sustainable.

“We’re demonstrating a process of taking trash and turning it into a useful insecticide. And it’s really opened a whole new avenue to produce a variety of ecologically safe chemicals using the same approach,” said Crossley.

More information:

Tejas Goculdas et al, Biomass‐Derived, Target Specific, and Ecologically Safer Insecticide Active Ingredients, ChemSusChem (2024). DOI: 10.1002/cssc.202400824

Citation:

Bio-based insecticidal ingredients have the potential to drive ecologically safer pesticides (2024, September 24)

retrieved 24 September 2024

from https://phys.org/news/2024-09-bio-based-insecticidal-ingredients-potential.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.